- info@matltech.com

- E2-1-1011 Global Centre, No.1700 Tianfu Avenue North, Chengdu 610041, China.

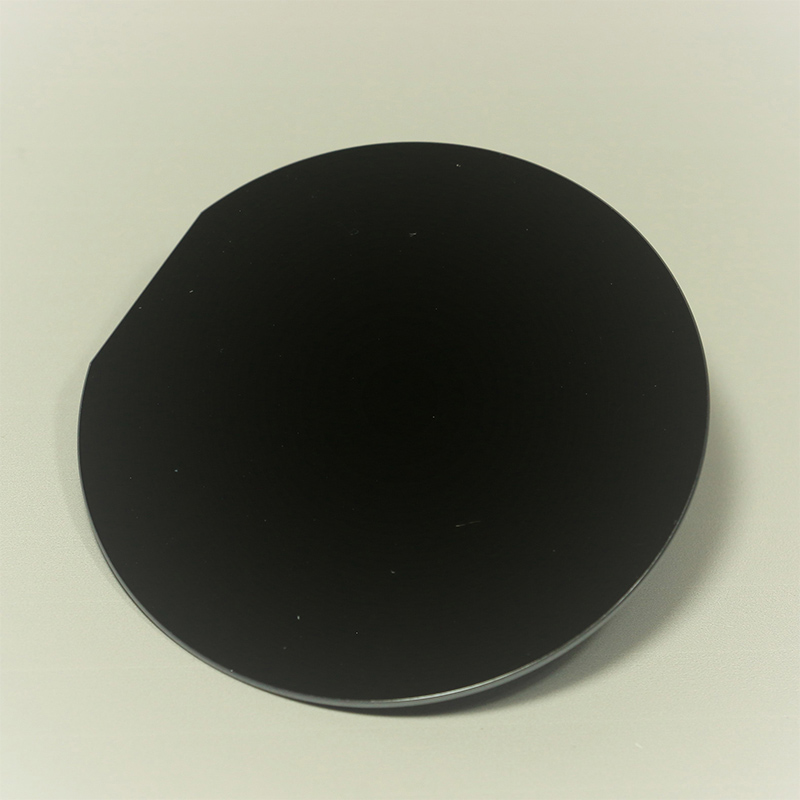

CZ Silicon Wafer

Inkcazo

CZ Single Crystal Silicon Wafer inqunyulwe ukusuka kwi-crystal silicon ingot enye itsalwa yindlela yokukhula yeCzochralski CZ, esetyenziswa kakhulu ekukhuleni kwe-silicon crystal yee-ingots ezinkulu ze-cylindrical ezisetyenziswa kwishishini lombane ukwenza izixhobo ze-semiconductor.Kule nkqubo, imbewu encinci ye-crystal silicon kunye nokunyamezela okuchanekileyo kufakwa kwibhafu etyhidiweyo ye-silicon ebushushu bayo bulawulwa ngokuchanekileyo.Ikristale yembewu itsalwa ngokucothayo ukuya phezulu ukusuka ekunyibilikeni ngesantya esilawulwa kakhulu, ukuqina kwecrystalline yee-athom ukusuka kwinqanaba lolwelo kwenzeka kwi-interface, ikristale yembewu kunye ne-crucible zijikeleziswa kumacala achaseneyo ngexesha lenkqubo yokurhoxiswa, kudala enye enkulu. isilicon yekristale enesakhiwo sekristale esigqibeleleyo sembewu.

Ngombulelo kumhlaba wemagnethi osetyenziswa kutsalo lwe-CZ ye-ingot esemgangathweni, i-Czochralski MCZ i-silicon enye yekristale ye-Czochralski inomlinganiselo ophantsi wokungacoceki, inqanaba elisezantsi le-oksijini kunye nokuchithwa, kunye nokwahluka okufanayo kokumelana nokusebenza kakuhle kubuchwepheshe obuphezulu bezixhobo ze-elektroniki kunye nezixhobo. ukuveliswa kumashishini e-elektroniki okanye e-photovoltaic.

Ukuhanjiswa

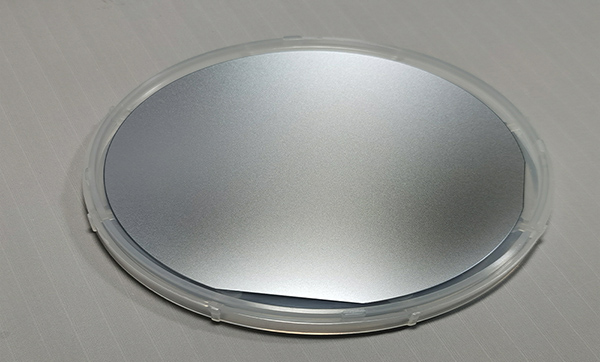

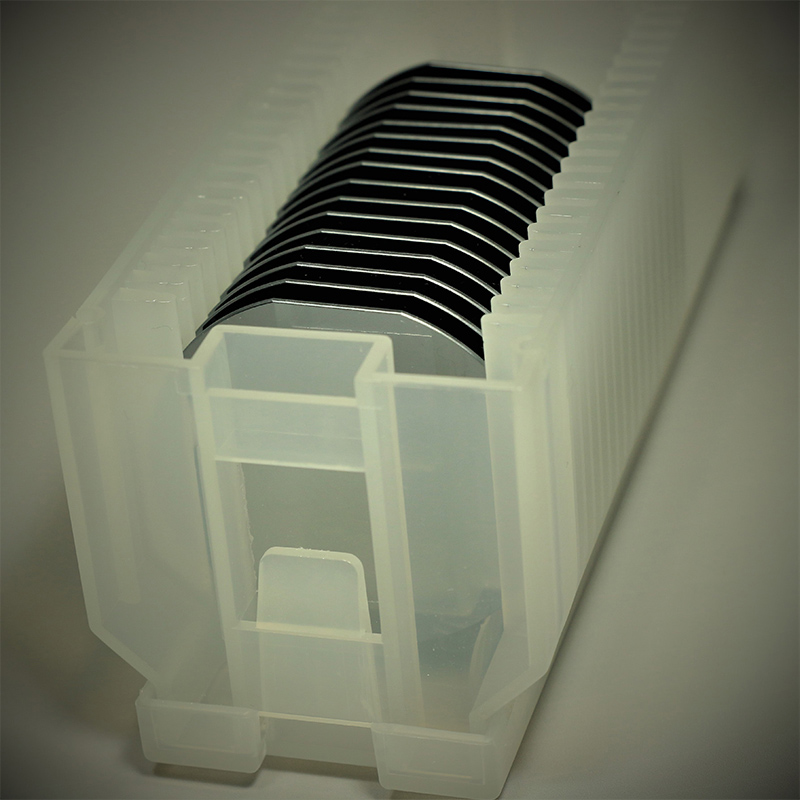

CZ okanye MCZ Single Crystal Silicon Wafer n-uhlobo kunye p-uhlobo conductivity at Western Minmetals (SC) Corporation zingahanjiswa ngobukhulu 2, 3, 4, 6, 8 kunye 12 intshi ububanzi (50, 75, 100, 125, 150, 200 kunye ne-300mm), i-orientation <100>, <110>, <111> enomphezulu ogqityiweyo ogqitywe, waqanjwa kwaye wapolishwa kwiphakheji yebhokisi yogwebu okanye ikhasethi enebhokisi yebhokisi ngaphandle.

Iinkcukacha

Iithegi

Inkcazo yobuGcisa

CZ Single Crystal Silicon Wafer yinto esisiseko kwimveliso yeesekethe ezidibeneyo, i-diodes, i-transistors, i-discrete components, esetyenziswa kuzo zonke iintlobo zezixhobo ze-elektroniki kunye nezixhobo ze-semiconductor, kunye ne-substrate kwi-epitaxial processing, i-SOI wafer substrate okanye i-semi-insulating compound wafer fabrication, ngokukodwa enkulu. Idayamitha ye-200mm, 250mm kunye ne-300mm zezona zifanelekileyo ukwenza izixhobo ezidityanisiweyo kakhulu.I-Crystal Silicon enye isetyenziselwa iiseli zelanga ngobuninzi obukhulu yimboni ye-photovoltaic, ephantse ibe yikristale egqibeleleyo isakhiwo esivelisa ukukhanya okuphezulu kokuguqulwa kombane.

| Hayi. | Izinto | Inkcazo esemgangathweni | |||||

| 1 | Ubungakanani | 2" | 3" | 4" | 6" | 8" | 12" |

| 2 | Ububanzi mm | 50.8±0.3 | 76.2±0.3 | 100±0.5 | 150±0.5 | 200±0.5 | 300±0.5 |

| 3 | Ukuqhuba | P okanye N okanye un-doped | |||||

| 4 | Ukuqhelaniswa | <100>, <110>, <111> | |||||

| 5 | Ukutyeba μm | 279, 381, 425, 525, 575, 625, 675, 725 okanye njengoko kufuneka | |||||

| 6 | Ukuxhathisa Ω-cm | ≤0.005, 0.005-1, 1-10, 10-20, 20-100, 100-300 njl. | |||||

| 7 | RRV ubuninzi | 8%, 10%, 12% | |||||

| 8 | IFlethi yokuqala/Ubude mm | Njengomgangatho we-SEMI okanye njengoko kufuneka | |||||

| 9 | IFlethi yesibini/Ubude mm | Njengomgangatho we-SEMI okanye njengoko kufuneka | |||||

| 10 | TTV μm max | 10 | 10 | 10 | 10 | 10 | 10 |

| 11 | I-Bow & Warp μm max | 30 | 30 | 30 | 30 | 30 | 30 |

| 12 | Umphezulu Gqiba | Njengoko-cut, L/L, P/E, P/P | |||||

| 13 | Ukupakisha | Ibhokisi yogwebu okanye ikhasethi ngaphakathi, ibhokisi yebhokisi ngaphandle. | |||||

| Uphawu | Si |

| Inombolo yeAtom | 14 |

| Ubunzima beAtom | 28.09 |

| Udidi lweNqanaba | Metalloid |

| Iqela, Ixesha, Block | 14, 3, P |

| Ubume beCrystal | Idayimani |

| Umbala | Ingwevu emnyama |

| Indawo yokunyibilika | 1414°C, 1687.15 K |

| Indawo yokubilisa | 3265°C, 3538.15 K |

| Ukuxinana kwi-300K | 2.329 g/cm3 |

| Ukuxhathisa kwangaphakathi | 3.2E5 Ω-cm |

| Inombolo yeCAS | 7440-21-3 |

| Inombolo yeEC | 231-130-8 |

CZ okanye MCZ Single Crystal Silicon WaferUdidi lwe-n kunye nohlobo lwe-p-conductivity kwi-Western Minmetals (SC) Corporation inokuhanjiswa ngobukhulu be-2, 3, 4, 6, 8 kunye ne-12 intshi ubukhulu (50, 75, 100, 125, 150, 200 kunye ne-300mm), i-orientation <100>, <110>, <111> kunye nokugqitywa komphezulu we-as-cut, i-lapped, ifakwe kwaye iphuculwe kwiphakheji yebhokisi yogwebu okanye ikhasethi enebhokisi yebhokisi ngaphandle.

Iingcebiso zokuthengwa kwempahla

- Isampulu Ifumaneka Ngesicelo

- Ukuhanjiswa ngoKhuseleko kweMpahla ngeCourier/Air/elwandle

- Ulawulo loMgangatho we-COA/COC

- Ukupakisha okukhuselekileyo nokufanelekileyo

- Ukupakishwa okusemgangathweni kwe-UN kuFumaneka ngesicelo

- ISO9001:2015 Certified

- Imigaqo yeCPT/CIP/FOB/CFR Nge-Incoterms 2010

- I-Flexible Pay Terms T/TD/PL/C Yamkelekile

- Iinkonzo ezipheleleyo zasemva kokuthengiswa

- Ukuhlolwa koMgangatho NgeZiko leSate-of-the-art

- Rohs/REACH Regulations Regulations

- Izivumelwano ezingaxeliyo NDA

- Umgaqo-nkqubo weziMbiwa oNgachasananga

- Uphononongo loLawulo lokusiNgqongileyo rhoqo

- Ukufezekiswa koXanduva lweNtlalo

CZ Silicon Wafer

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu