- info@matltech.com

- Iziko le-E2-1-1011 leHlabathi, i-177 Tianfu Avenue North, Chengdu 610041, China

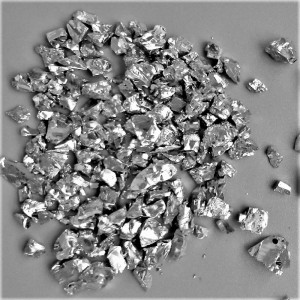

Ingxubevange yeCopperurium yeTellurium

Ingxubevange yeCopperurium yeTellurium, ngokongeza kancinci ubunzima beepesenti ye-99.99% ye-tellurium emsulwa kwintengiso etyhidiweyo ye-9.99% ye-cathode yobhedu kwiziko lokunyanzeliswa kwamandla, kwaye okwangoku enye ye-phosphorus njenge-deoxidant kunye nezinto ezincinci ezifunekayo ziyongezwa kulwelo olutyhidiweyo ukuze lufuneke I-alumurium ingxubevange yobhedu.

Ukusebenza okuphezulu okusika simahla, okuvumela isantya sokumakatha esiphezulu kunokuba kunokwenzeka ngobhedu olusulungekileyo, isikali sokukwazi ukulinganiswa sikalwe njenge-90, zombini ukusebenza okubandayo okanye ukubumba okushushu kuyenzeka, kwaye ngokusebenza okuhle kokumelana ne-arc, i-hydrogen embrittlement, ephezulu Ukuqhutywa kombane (i-90% ye-IACS) kunye nokuqhutywa kwe-thermal, kunye ne-anti-corrosiveness, iTellurium Copper Alloy (C14500, CuTeP) isetyenziselwa ukuwelda (ukusika i-hydrogen, ukusika i-acetylene kunye nesixhobo se-argon-arc welding), ishishini lamachiza kunye noomatshini bezimbiwa Imoto yombhobho we-carburetor, iingcebiso zetotshi, i-nozzle yokusika igesi, intloko yokugcina ibhetri kunye nesinxibelelanisi semeko yomoya, ukutshintshela umbane kwii-semiconductors zamandla, iitransformer kunye neeterminal breaker terminals, tshintsha iigesi kunye nokuveliswa kwevalve njl.

Zonke iimveliso zihambelana nemigaqo yeRoHS.

Iinkcukacha

Iimpawu

Ukucaciswa kobuchwephesha

|

Hayi. |

Umba |

Ukucaciswa okusemgangathweni |

|||

|

1 |

IBakala |

Te |

Re |

P |

Cu |

|

2 |

Te-Cu |

0.2-0.35% |

0.03-0.05% |

- |

ibhalansi |

|

3 |

I-Te-P-Cu |

0.4-0.70% |

- |

0.004-0.012% |

ibhalansi |

|

4 |

Ubunzima |

H04, H02, O60 |

|||

| Tensile Strength |

265 iMpa Min |

||||

| Ukudibanisa |

8% Min |

||||

| Ukuqhuba kombane |

I-90% ye-IACS Min |

||||

| Inqanaba lokungasebenzi kakuhle |

90 Min [isekwe kwi-HPb 63-3 (C36000)] |

||||

|

5 |

Ubungakanani | I-D90 mm × L (0.25-5) m, eyongezelelweyo D (5-40) mm × L (0.25-5) m | |||

|

6 |

Imigangatho |

Inkcazo: ASTM-C14500 / GB-QTe0.5 / JIS-C1450 / DIN-CuTeP / BS-C109 |

|||

|

7 |

Ukupakisha |

Kwimeko yeplywood |

|||

Iingcebiso zokuthenga

- Isampuli iyafumaneka emva kwesicelo

- Ukuhanjiswa koKhuseleko lweZinto ngeKhuriya / yoMoya / yoLwandle

- Ulawulo loMgangatho we-COA / COC

- Ukupakisha okuKhuselekileyo nokuKhuselekileyo

- Ukupakishwa okusemgangathweni kwe-UN kuyafumaneka ngesicelo

- Ukuhlolwa koMgangatho kubandakanya iXRD / SEM / ICP / GDMS njl

- Ububanzi obupheleleyo beMigaqo yoRhwebo CPT / FOB / CFR / CIP NguIncoterms 2010

- Imiqathango yeNtlawulo yeFlexible T / TD / PL / C yamkelekile

- IiNkonzo eziPheleleyo zokuThengisa emva kokuThengisa

- I-ISO9001: I-2015 eqinisekisiweyo kunye neeRohs / REACH Imigaqo yokuvunywa

- Izivumelwano ezingachazwanga

- Umgaqo-nkqubo Wezimbiwa Ongangqubaniyo

- Ukuphononongwa rhoqo koLawulo lokusiNgqongileyo

- Ukufezekiswa koxanduva lokuhlala

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu